Aluminum profile is used in a wide variety of applications across a wide variety of industries due to its resistance to corrosion, high strength-to-weight ratio, and ability to be worked. These characteristics allow aluminum profile to be worked. Welding can also be written with a noun form.

It is possible to produce a connection between two or more sections that is both stable and long-lasting if you make use of welding techniques such as gas metal arc welding (GMAW), gas tungsten arc welding (GTAW), and metal inert gas (MIG) welding. These techniques involve the use of an electric arc to join two or more pieces of material together.

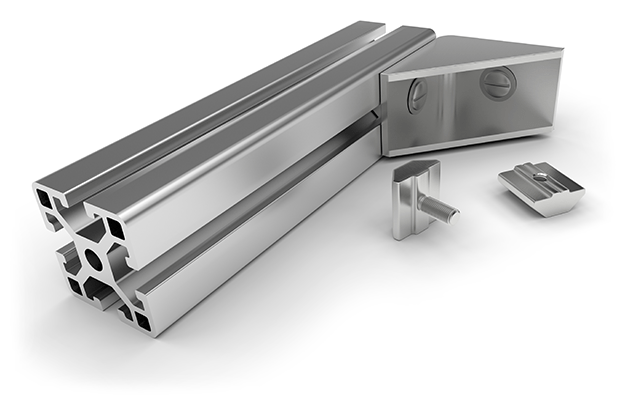

The utilization of fasteners such as screws, bolts, and nuts enables not only simple assembly but also simple disassembly in the event that it is necessary. Because of their adaptability and flexibility, the applications for fasteners can cover an extremely wide range of possibilities. It is a standard procedure to protect fasteners from corrosion by plating the surface of the fasteners with a material made of zinc or cadmium.

Keeping our trust in one another as a top priority

Epoxy structural adhesives have the ability to form bonds that are not only able to last for a significant amount of time, but can also withstand vibration. This is a significant advantage over other types of structural adhesives. As a consequence of this, they are an excellent choice for applications that call for a variety of aluminum profiles that have complex geometries as a result of the fact that they have these characteristics.

Utilization of Rivets is especially the case for gauges that are thinner. Rivets are used to attach panels together.

Combination rivets are required whenever two or more materials of varying thicknesses are to be joined together. This includes situations where the thicknesses of the individual materials vary.

Adhesive bonding is a relatively new method of joining that makes use of high-performance structural liquid adhesives such as epoxy resins or acrylic acids. This method of joining is also relatively new. One of the more recent innovations in the industry is this method of joining pieces together. It is possible for it to form a bond that is both extremely long-lasting and irreversible in its nature after being subjected to heat in the manner described above. This is one of the possible results that could come from carrying out the process. This method is simple to use, naturally seamless, has a high resistance to impact, and only a limited number of restrictions on the size and shape of the Aluminum Profile that can be used. These benefits make it an attractive option.

The presentation is very impressive to look at, and it enables people to comprehend the arguments on both sides of the debate.

The friction plug welding technique makes use of a rotating pin or sleeve with a shouldered tip that generates heat through friction in order to plasticize and displace the aluminum as it is inserted. This allows the aluminum to be welded without cracking or breaking. Welding aluminum does not result in any cracking or breaking of the material because of this characteristic of the process. This self-piercing process can be used with materials that are not analogous to one another, and it leaves a neat weld on the frontside of the joint that it creates. Additionally, the process does not require the use of any additional tools or equipment. Because of this, it is suitable for uses such as automotive body panels in a variety of different applications.

There are also cutting-edge methods that can be used, such as flow drilling, which produces a connection that is form-fitting while simultaneously drilling and tapping screws in a single step. Flow drilling is just one example of a technique that can be used. Flow drilling is just one of the many methods available to you at this time; you also have access to a great deal of other options. The particular requirements of the task will serve as the primary factor that needs to be taken into consideration in order to arrive at a decision regarding the strategy that will be used to finish the project.

Search

Popular Posts