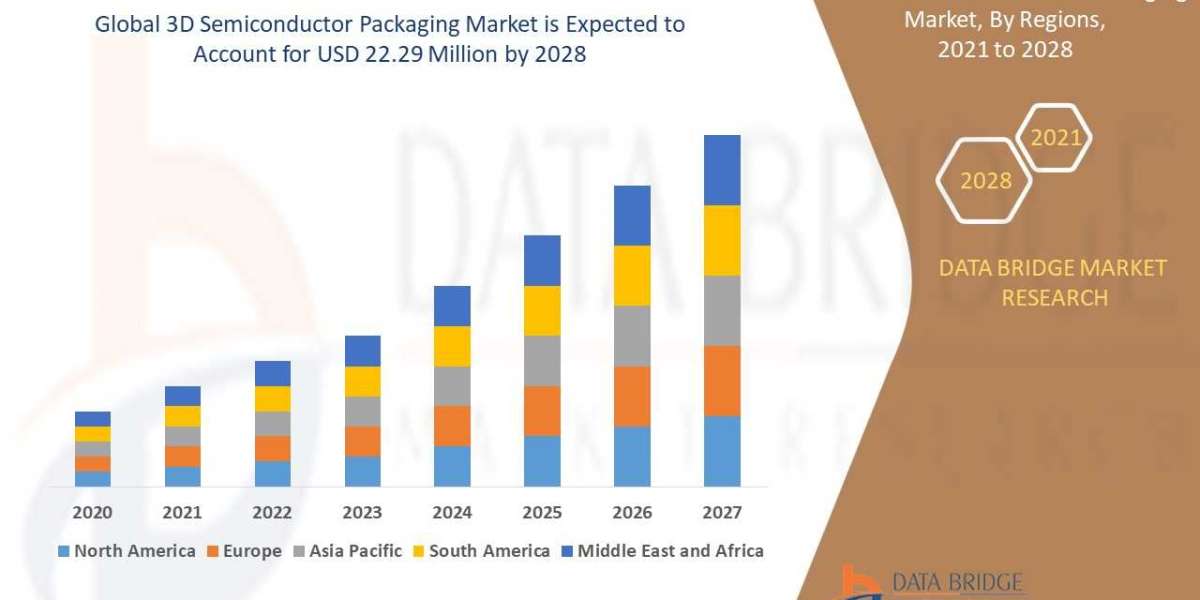

"3D Semiconductor Packaging Market – Industry Trends and Forecast to 2028

Global 3D Semiconductor Packaging Market, By Technology (3D Through silicon via, 3D Package on Package, 3D Fan Out Based, 3D Wire Bonded), Material (Organic Substrate, Bonding Wire, Leadframe, Encapsulation Resin, Ceramic Package, Die Attach Material), Industry Vertical (Electronics, Industrial, Automotive Transport, Healthcare, IT Telecommunication, Aerospace Defense), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350 Pages PDF Report @

https://www.databridgemarketresearch.com/reports/global-3d-semiconductor-packaging-market

**Segments**

- **By Type**: The 3D semiconductor packaging market can be segmented by type into 3D SIP (System in Package), 3D SIC (System in Chip), and 3D WLP (Wafer Level Packaging). 3D SIP involves integrating multiple chips and passive components into a single package, offering reduced form factor and improved performance. 3D SIC involves stacking multiple dies vertically, leading to shorter interconnects and enhanced performance. 3D WLP involves packaging at the wafer level, leading to smaller form factors and improved electrical performance.

- **By Packaging Technology**: The market can also be segmented by packaging technology, including Through-Silicon Via (TSV), Cu-Cu Bonding, and Micro-Bump technology. TSV allows vertical interconnects through the silicon wafer, enabling higher bandwidth and faster data transfer. Cu-Cu bonding involves bonding copper layers to connect chips, providing better conductivity and reliability. Micro-Bump technology utilizes small solder bumps for chip-to-chip interconnection, offering high density and fine pitch.

- **By End-User**: The 3D semiconductor packaging market can be segmented by end-user industry, such as consumer electronics, automotive, healthcare, aerospace, and telecommunications. Consumer electronics demand compact and high-performance devices, driving the adoption of 3D packaging solutions. The automotive sector requires rugged and reliable packaging for advanced driver assistance systems and electric vehicles. Healthcare applications benefit from miniaturization and enhanced performance offered by 3D packaging technologies. Aerospace and telecommunications industries also rely on 3D packaging for space-saving and improved functionality.

**Market Players**

- **Advanced Semiconductor Engineering, Inc.**: A leading provider of semiconductor packaging and testing services, offering advanced solutions for various applications.

- **Amkor Technology**: Specializes in advanced semiconductor packaging and test services, catering to a wide range of industries and applications.

- **ASE Group**: A global provider of semiconductor manufacturing and packaging services, servingThe 3D semiconductor packaging market is witnessing significant growth and innovation across various segments, including type, packaging technology, and end-user industries. By type, the market is segmented into 3D SIP, 3D SIC, and 3D WLP, each offering unique advantages in terms of form factor reduction, performance enhancement, and electrical performance improvements. 3D SIP integrates multiple chips and passive components into a single package, catering to the demand for compact and high-performance devices in consumer electronics. Meanwhile, 3D SIC focuses on stacking multiple dies vertically to reduce interconnect lengths and enhance performance, making it ideal for applications in automotive and telecommunications sectors where reliability and improved functionality are crucial. On the other hand, 3D WLP, which involves packaging at the wafer level, offers smaller form factors and superior electrical performance, benefiting industries like healthcare and aerospace that require miniaturization and enhanced performance.

In terms of packaging technology, the market is segmented by Through-Silicon Via (TSV), Cu-Cu Bonding, and Micro-Bump technology, each playing a vital role in enabling advanced 3D semiconductor packaging solutions. TSV technology allows vertical interconnects through the silicon wafer, leading to higher bandwidth and faster data transfer rates, making it suitable for high-performance computing and telecommunications applications. Cu-Cu bonding, on the other hand, provides better conductivity and reliability by bonding copper layers to connect chips, offering improved thermal management and electrical performance. Micro-Bump technology utilizes small solder bumps for chip-to-chip interconnection, facilitating high-density integration and fine-pitch interconnects, making it ideal for applications where space-saving and improved functionality are essential.

The 3D semiconductor packaging market caters to a broad spectrum of end-user industries, including consumer electronics, automotive, healthcare, aerospace, and telecommunications, each with specific requirements and demands for advanced packaging solutions. Consumer electronics industry drives the adoption of 3D packaging technologies to meet the demand for**Segments:**

- **By Type:** The 3D semiconductor packaging market can be segmented by type into 3D SIP (System in Package), 3D SIC (System in Chip), and 3D WLP (Wafer Level Packaging). Each type offers unique advantages in terms of form factor reduction, performance enhancement, and electrical performance improvements. 3D SIP integrates multiple chips and passive components into a single package, catering to the demand for compact and high-performance devices in consumer electronics. Meanwhile, 3D SIC focuses on stacking multiple dies vertically to reduce interconnect lengths and enhance performance, making it ideal for applications in automotive and telecommunications sectors where reliability and improved functionality are crucial. 3D WLP, which involves packaging at the wafer level, offers smaller form factors and superior electrical performance, benefiting industries like healthcare and aerospace that require miniaturization and enhanced performance.

- **By Packaging Technology:** The market can also be segmented by packaging technology, including Through-Silicon Via (TSV), Cu-Cu Bonding, and Micro-Bump technology. TSV technology allows vertical interconnects through the silicon wafer, leading to higher bandwidth and faster data transfer rates, suitable for high-performance computing and telecommunications applications. Cu-Cu bonding provides better conductivity and reliability by bonding copper layers to connect chips, offering improved thermal management and electrical performance. Micro-Bump technology utilizes small solder bumps for chip-to-chip interconnection, facilitating high-density integration and fine-p

Table of Content:

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Global 3D Semiconductor Packaging Market Landscape

Part 04: Global 3D Semiconductor Packaging Market Sizing

Part 05: Global 3D Semiconductor Packaging Market Segmentation by Product

Part 06: Five Forces Analysis

Part 07: Customer Landscape

Part 08: Geographic Landscape

Part 09: Decision Framework

Part 10: Drivers and Challenges

Part 11: Market Trends

Part 12: Vendor Landscape

Part 13: Vendor Analysis

3D Semiconductor Packaging Key Benefits over Global Competitors:

- The report provides a qualitative and quantitative analysis of the 3D Semiconductor Packaging Market trends, forecasts, and market size to determine new opportunities.

- Porter’s Five Forces analysis highlights the potency of buyers and suppliers to enable stakeholders to make strategic business decisions and determine the level of competition in the industry.

- Top impacting factors major investment pockets are highlighted in the research.

- The major countries in each region are analyzed and their revenue contribution is mentioned.

- The market player positioning segment provides an understanding of the current position of the market players active in the Personal Care Ingredients

Browse Trending Reports:

Point Of Care Ultrasound Systems Pocus Market

Milk Alternatives Market

Jewellery Boxes Market

Type c Bulk Bags Market

Hypertrophic And Keloid Scar Treatment Market

Solid Bleached Sulfate Sbs Board Market

Text To Speech Market

Gluten Free Alcohol Market

Search Engine Optimization Seo Advertising Software Market

Cytokinin Market

Pharmaceuticals Market

Hemp Derived Cannabidiol Market

Water Soluble Npk Fertilizers Market

Portable Compressor Nebulizer Market

Missile And Air Defense Radar System Market

Hotel Armchair Market

Fuel Cells Marine Vessels Market

Sound Enclosure Commercial Beverage Blender Market

Bone Conduction Hearing Aids Market

Hearing Amplifiers Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975