It is possible to conduct research into the history of springs, which dates back through the centuries. However, over the course of history, springs have developed into a number of distinct types, one of which is known as the torsion spring.

You might be curious about the specifics of what a torsion spring is.

- Torsion springs are a specific type of spring that store mechanical energy by requiring the user to twist the spring in order to store the energy

- This action is required in order for the spring to store the energy

- Torsion springs are a common component in a variety of different types of mechanical devices

- They will also generate torque in the direction that is counter to the direction in which they were initially twisted, which is the direction in which they were twisted when they were first created

The majority of mouse traps use a torsion spring manufacturer as their primary source of tension, and this is true for almost all of them. The torsion spring supplier in question is known as a helical torsion spring, and it is distinguished from other types of torsion springs by the incorporation of both a coiled piece of metal and a rod into its overall construction. You will be able to store mechanical energy in the coiled piece of metal because it will be caused to twist when you apply pressure to the rod. The rod itself will have the ability to store the energy. There are many examples of this, such as mouse straps, which can be found in a variety of places.

The vast majority of torsion springs are constructed with stainless steel as their primary material of construction. This is the case for almost all torsion springs. Another advantage of using this material is that it is resistant to corrosion, which helps to ensure that torsion springs made from this material have a longer lifespan than those made from other materials. Stainless steel is by far the material that is used the most frequently when making torsion springs, despite the fact that torsion springs can be fabricated from a very wide variety of metals and alloys.

There is absolutely no way that extension springs and torsion springs can be switched out for one another in any way. The length of the extension spring is going to get longer in direct proportion to the amount that the two components are going to try to get further apart from one another. This is because the length of the extension spring is directly proportional to the length of the extension spring. When pressure from the weight of a load is applied to them, all that happens is that they rotate. Torsion springs are designed to turn in a direction that is counterclockwise to their axis, so when they are subjected to a load, they will turn in this direction around their axis. After being twisted, they will be able to store the mechanical energy that is transferred to them by the load. This energy will be used later. Another common kind of spring that you might run into is known as a compression spring. To put it another way, extension springs are the complete antithesis of compression springs in every conceivable way. Extension springs are also known as torsion springs. The extension spring is the most common and versatile type of spring.

The Complete Reference Guide to Everything You Need to Know About Torsion Springs

This entry of our blog series titled "All About Springs," which is dedicated to talking about various types of springs, is going to be devoted to discussing torsion springs as the topic of conversation. Torsion springs, in addition to compression springs and extension springs, are present in a significant number of products that are used on a regular basis. This is the case for all three types of springs. These products span a wide range of categories, each catering to a specific need. The image on the right makes it abundantly clear that the spring that is responsible for holding the two wooden clamps together is a torsion spring. This information can be found by looking to the right of the image. Despite the fact that their mode of operation is distinct from that of extension and compression springs, torsion springs continue to be among the most popular and widely used types of springs all over the world. This is true despite the fact that torsion springs are one of the most common types of springs. Torsion springs are quite comparable to extension springs in the sense that, just like extension springs, torsion springs need to have other components attached to them at both ends in order for them to work properly.

The application of external forces to the ends of a torsion spring supplier (see game items) causes the spring's individual coils to move closer to one another so that the spring can accommodate the increased tension.

The conventional method for securing torsion springs in their allotted positions is to mount the springs on a mandrel, which is a thin rod or peg that can be inserted into the coils of the spring. The fixture needs to have just the right amount of tightness so that it does not allow for excessive play, but it also needs to have just the right amount of looseness so that it does not restrict full motion. This is necessary in order for the fixture to function properly. In some instances, such as the one with the clothespin, the ends of the spring are constructed in such a way that they provide a secure connection between the spring and the parts that are adjacent to it. This connection prevents the spring from becoming disconnected from the parts that are adjacent to it. Because of this connection, the spring cannot move in relation to the components that are located immediately to its left and right.

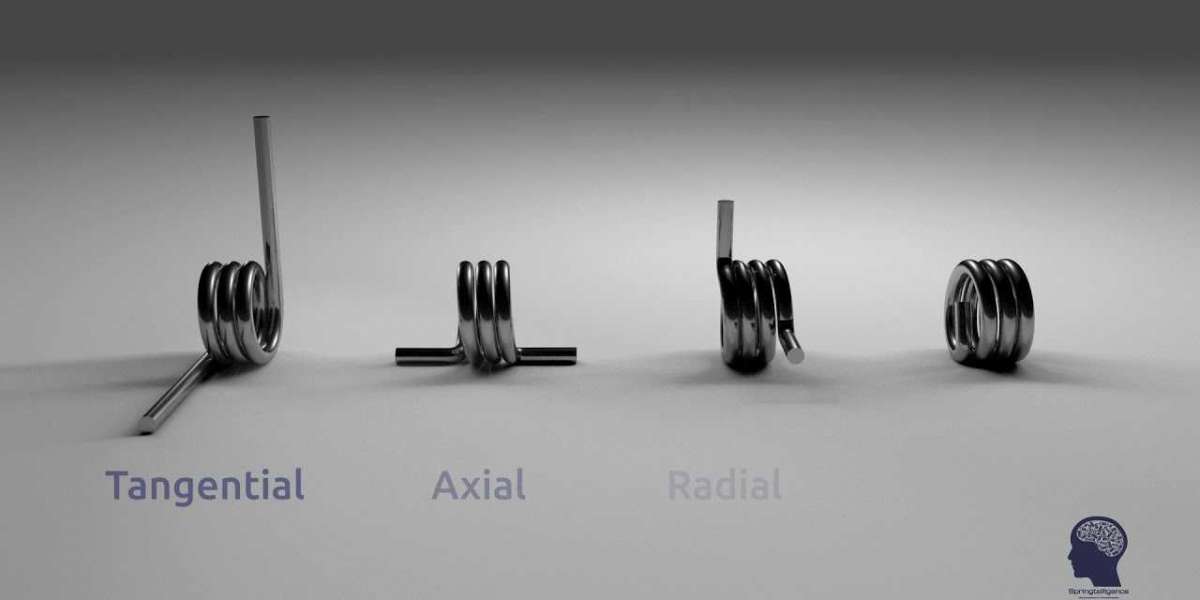

Torsion springs are available in a variety of configurations, including double, right hand, and left hand, depending on the application for which they are being used. The more common type of torsion spring manufacturer is the left hand variety.

The production of torsion springs is one of the many things that we (Manufacturing) are responsible for.

Torsion Spring Winding and Winding Machine, Model AIM 2000 Winding and Winding MachineMachine for Winding Torsion Springs and Winding Springs for Torsion SpringsWhen calibrating a spring coiling machine to produce torsion springs, in the same way that this must be done for any other type of spring, a number of different parameters must be taken into consideration. This is similar to the process that must be followed when calibrating the machine to produce any other type of spring. When calibrating the machine to produce any other kind of spring, the process is very similar to this one, and it is necessary to follow it. Those who are in charge of the design of torsion springs are obligated to take into consideration the following aspects, in addition to the overall dimensions and contours of the springs:

The rate of a spring is a measurement of the amount of force that is required in order to exert an effect on the spring. One way to think about the rate of a spring is as a measurement of the amount of force that is required.

However, the vast majority of torsion springs are close wound. Some torsion springs, on the other hand, are wound with pitch in order to reduce friction.

The formation of the wire occurs at the ends of the coil, and it is at these ends that the wire is attached to the various components found on the outside. For example, torsion springs cannot be made to work with compression springs because the ends of compression springs are plain. This prevents the two types of springs from being interchangeable. Because of this, the two different types of springs cannot be used in conjunction with one another. Single-point coilers have a significantly broader range of capabilities than multipoint coilers, which allows them to accomplish a greater variety of jobs. Multipoint coilers can only handle a limited number of jobs. Customers have the option of selecting from a number of different CNC spring coilers that are made available by Automated Industrial Motion (AIM). These CNC spring coilers have the capacity to produce torsion springs that are in accordance with the requirements of virtually any specification.