In the world of manufacturing, efficiency and productivity are key factors for success. Industrial fixed-bed production units have emerged as a revolutionary solution to enhance manufacturing processes across various industries. This article aims to provide a comprehensive understanding of industrial fixed-bed production units, including their definition, working principles, key components, configuration and layout, applications, and benefits.

Understanding Industrial Fixed-Bed Production Units

Industrial fixed-bed production units are advanced manufacturing systems designed to optimize production processes. They consist of a fixed bed, which is a solid structure that holds the materials being processed, and a series of interconnected components that facilitate the manufacturing process. These units are widely used in industries such as petrochemicals, pharmaceuticals, food processing, and chemical manufacturing.

Definition of Industrial Fixed-Bed Production Units

Industrial fixed-bed production units are specialized systems that utilize a fixed bed of materials to carry out various manufacturing processes. The fixed bed acts as a support structure for the materials being processed, allowing for controlled reactions and efficient production. These units are designed to handle large volumes of materials and can be customized to meet specific manufacturing requirements.

Working Principles of Industrial Fixed-Bed Production Units

The working principles of industrial fixed-bed production units involve the controlled flow of materials through the fixed bed. The materials are introduced into the unit and pass through the fixed bed, where they undergo various physical or chemical transformations. The fixed bed provides a stable environment for the materials, ensuring uniform contact and reaction. The flow of materials can be regulated by adjusting the pressure, temperature, and flow rate within the unit.

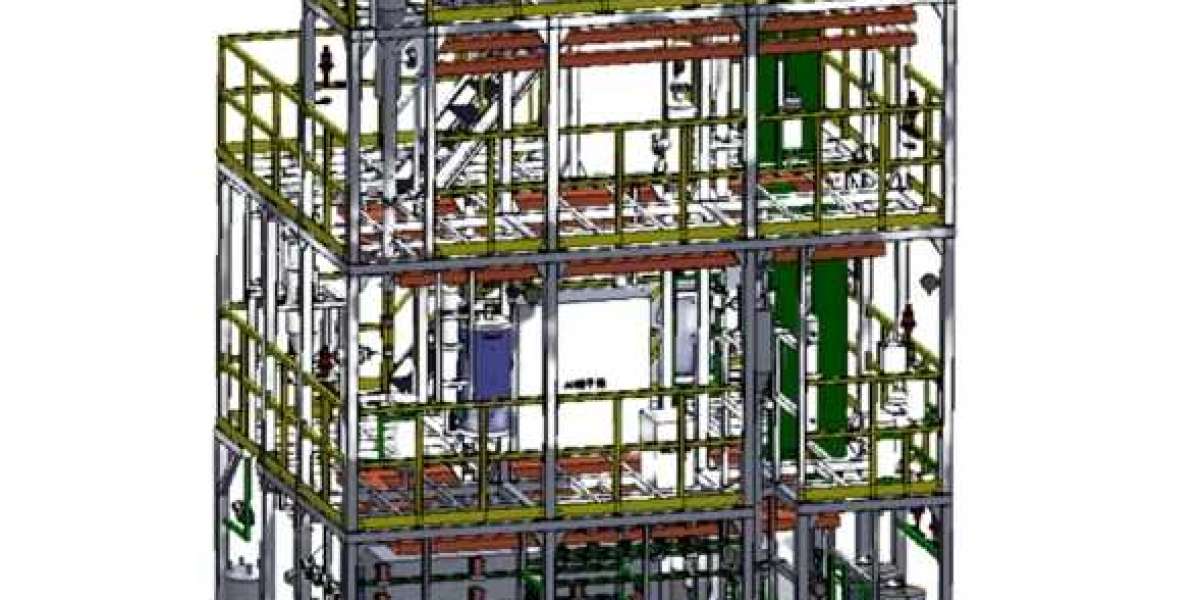

Key Components of Industrial Fixed-Bed Production Units

Industrial fixed-bed production units consist of several key components that work together to facilitate the manufacturing process. These components include:

Reactor: The reactor is the main vessel where the materials undergo the desired reactions. It is typically made of high-quality materials that can withstand the harsh conditions of the manufacturing process.

Catalyst: In many cases, industrial fixed-bed production units utilize catalysts to enhance the efficiency of the reactions. Catalysts are substances that promote chemical reactions without being consumed in the process.

Feed System: The feed system is responsible for introducing the materials into the reactor. It ensures a controlled and continuous flow of materials through the fixed bed.

Heat Exchanger: Heat exchangers are used to regulate the temperature within the unit. They help maintain optimal conditions for the reactions and prevent overheating or cooling.

Separator: After the materials have undergone the desired reactions, a separator is used to separate the desired products from any remaining impurities or by-products.

Configuration and Layout of Industrial Fixed-Bed Production Units

The configuration and layout of industrial fixed-bed production units vary depending on the specific manufacturing process and industry requirements. However, there are some common elements that can be found in most units. These include:

Inlet and Outlet Ports: These ports allow for the introduction and removal of materials from the unit. They are strategically placed to ensure a smooth flow of materials through the fixed bed.

Control System: A control system is essential for monitoring and regulating the various parameters within the unit, such as temperature, pressure, and flow rate. It ensures that the manufacturing process remains within the desired specifications.

Safety Measures: Industrial fixed-bed production units are equipped with safety measures to protect operators and prevent accidents. These measures may include emergency shutdown systems, pressure relief valves, and gas detection systems.

Applications of Industrial Fixed-Bed Production Units

Industrial fixed-bed production units find applications in a wide range of industries. Some common applications include:

Petrochemical Industry: These units are used for the production of various petrochemicals, such as ethylene, propylene, and benzene. They enable efficient and controlled reactions, leading to high-quality products.

Pharmaceutical Industry: Industrial fixed-bed production units are utilized in pharmaceutical manufacturing processes, such as the synthesis of active pharmaceutical ingredients (APIs). They ensure precise control over reaction conditions, resulting in consistent product quality.

Food Processing Industry: These units are employed in food processing for various purposes, such as the production of edible oils, hydrogenation of fats, and the synthesis of food additives. They enable efficient and safe processing of food materials.

Chemical Manufacturing: Industrial fixed-bed production units are widely used in the chemical industry for the production of chemicals, such as ammonia, methanol, and formaldehyde. They provide a controlled environment for chemical reactions, ensuring high yields and purity.

Benefits of Industrial Fixed-Bed Production Units

Industrial fixed-bed production units offer several benefits that make them a preferred choice in manufacturing processes. Some key benefits include:

Enhanced Efficiency: These units allow for precise control over reaction conditions, resulting in higher efficiency and productivity. The fixed bed provides a stable environment for reactions, ensuring uniform contact between materials and catalysts.

Improved Product Quality: The controlled environment provided by industrial fixed-bed production units leads to consistent product quality. The uniform contact between materials and catalysts ensures that reactions occur under optimal conditions, resulting in high-quality products.

Cost Savings: By optimizing manufacturing processes, industrial fixed-bed production units can lead to cost savings. The efficient use of materials, reduced energy consumption, and increased productivity contribute to overall cost reduction.

Safety and Environmental Benefits: Industrial fixed-bed production units are designed with safety measures to protect operators and prevent accidents. Additionally, the controlled reactions and efficient use of resources contribute to environmental sustainability.

Conclusion

Industrial fixed-bed production units have revolutionized manufacturing processes across various industries. Their ability to provide a controlled and efficient environment for reactions has led to enhanced efficiency, improved product quality, cost savings, and safety benefits. As manufacturing continues to evolve, these units will play a crucial role in driving innovation and productivity in the industry.

Related News:Industrial Fixed-Bed Production Units: An Overview of Design, Operation, and Applications